Procedure - Rehabilitating drinking water pipes

No dust, no noise.

Why you can count on the Promotec® system.

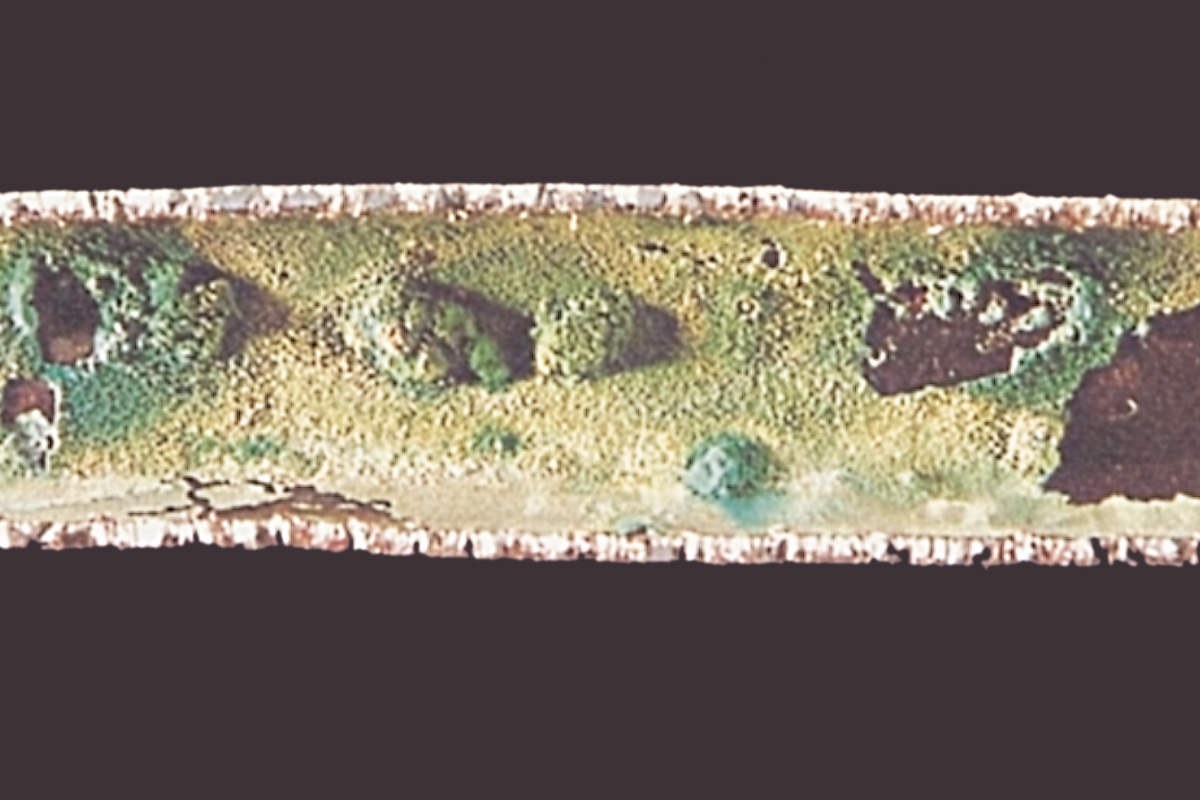

The process begins with the bare metal cleaning of the pipes. Our wet cleaning process, patented in 1993, which cleans gently and thoroughly, is special. This means that even very worn pipes that have already been punctured can be cleaned clean.

The Promotec® wet cleaning process

We are the only provider able to clean until the pipe is really clean everywhere. Conventional cleaning using the ‘dry method’ is very destructive in comparison, especially in the bends.

In order to achieve the all-important cleaning quality, another speciality of the Promotec process is that the entire pipe system is cleaned ‘forwards’ and ‘backwards’.

There are therefore no uncleaned shadow zones in the Promotec® process. The dry process can only be used to clean in one direction from small to large; the reverse is not possible, as the pipes become clogged when cleaning from large to small.

In the second process step, the pipes are dried and roughened with fine sand, which ensures perfect adhesion of the coating material.

In the third process step, the pipes are seamlessly sealed and protected on the inside with a special coating. The quality achieved is in no way inferior to new plastic pipes.

The Promotec system, patented in 1993, is unique and has proven itself thousands of times over. A Promotec coating protects the pipes for many decades.

Promotec process demo film short (75 sec.)

Promotec process demo film long( 4.5 min)

The following pipes can be renovated:

The Promotec system is suitable for all metal water pipes from 5 to 80 mm in diameter.

- Galvanised drinking water pipes (cold and hot water)

- Copper drinking water pipes

- Swimming pool pipes

- Fire extinguishing lines

- Heating pipes(copper / steel)

- Plastic pipes cannot be coated

Why do pipes rust?

In water pipes made of galvanised iron pipes or copper, rust and/or limescale deposits inevitably form after around 10 to 15 years. There are many different reasons for this. There are more than 100 known reasons why pipes rust (mixed water, aggressive water quality, water ingress, poor pipe quality, high temperatures, etc.). Some of the reasons are

- At temperatures above 60°C, a protective layer no longer forms in galvanised steel pipes.

Impurities in the water, aggressive, acidic, hard water. - Flow velocities and turbulence are also important factors in corrosion processes.

- Pitting in copper pipes due to extraneous rust washed into the pipes in water with a high carbon dioxide or chloride content.

- The hardening agent lime precipitates and forms scale - not uncommon with carbonate hardness of more than approx. 20° .

- Blunt thread-cutting blades destroyed the structure in the pipe - the finest cracks were unprotected and corrosion began.

- Old thread-cutting oil was used during assembly - the zinc coating was chemically attacked.

Erosion corrosion due to sand washed in.